How SnoFox Drives Emissions Reductions in Cold Storage

As a sustainability professional, you know the challenge all too well. Industrial refrigeration systems consume 60-70% of a cold storage facility's total energy, yet the necessity to keep things cold makes much of this consumption not easily abatable. That makes refrigeration your biggest sustainability challenge, while also being your greatest opportunity for impact.

The problem? Traditional cold storage monitoring only shows facility-wide consumption, leaving sustainability professionals without the precise data needed to drive meaningful reductions in both emissions and cost.

Granular Visibility that Drives Results

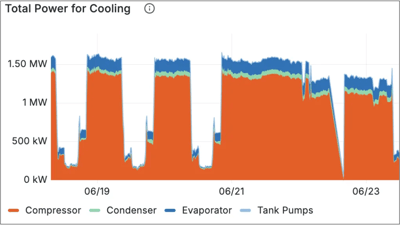

Unavailable in traditional systems, Total Power for Cooling transforms how you approach refrigeration energy management by providing the component-level visibility that's been missing. Using digital twin technology, SnoFox creates a virtual replica of your refrigeration system that breaks down total energy data into precise component-level consumption.

Instead of working with aggregate consumption data, you gain real-time insights into exactly what's happening within your refrigeration systems:

- Compressor performance (typically your largest energy consumer) shows you where most of your carbon footprint originates. When efficiency drops, you'll know immediately rather than discovering it weeks later through utility billing.

- Real-time monitoring captures those off-hours energy spikes that can undermine your sustainability goals. You get immediate visibility into consumption changes instead of waiting for monthly reports.

- Component-level tracking reveals which system elements are performing optimally and which need attention. You get complete visibility into how each piece of your refrigeration system is operating.

Here's a key advantage: When compressor consumption increases unexpectedly, you can calculate the additional CO2e emissions this represents and take corrective action before it impacts your carbon reduction targets.

Increase Efficiency to cut Emissions

Coefficient of Performance (COP) measures how efficiently your refrigeration system delivers cooling relative to energy consumed. This metric is valuable for sustainability professionals because higher COP values translate directly to lower emissions per unit of cooling delivered.

Actual vs. Ideal comparison reveals exactly how much energy your facility consumes above optimal levels. This gap represents inefficiencies and emissions reduction opportunities.

By tracking COP trends and identifying optimal operating conditions, you can implement targeted efficiency improvements that deliver measurable environmental impact.

Why Precision matters for Sustainability Professionals

Today's sustainability landscape demands measurable results backed by credible data. Management expects data-driven results, and regulatory requirements continue to evolve. Managing sustainability initiatives with facility-wide energy data limits your ability to identify specific improvement opportunities and quantify actual impact. This approach makes it challenging to develop targeted strategies or demonstrate concrete progress.

SnoFox addresses these challenges by providing the actionable insights sustainability professionals need. Clear visibility into your largest emissions sources, targeted opportunities for efficiency improvements, and precise data for calculating carbon impact.

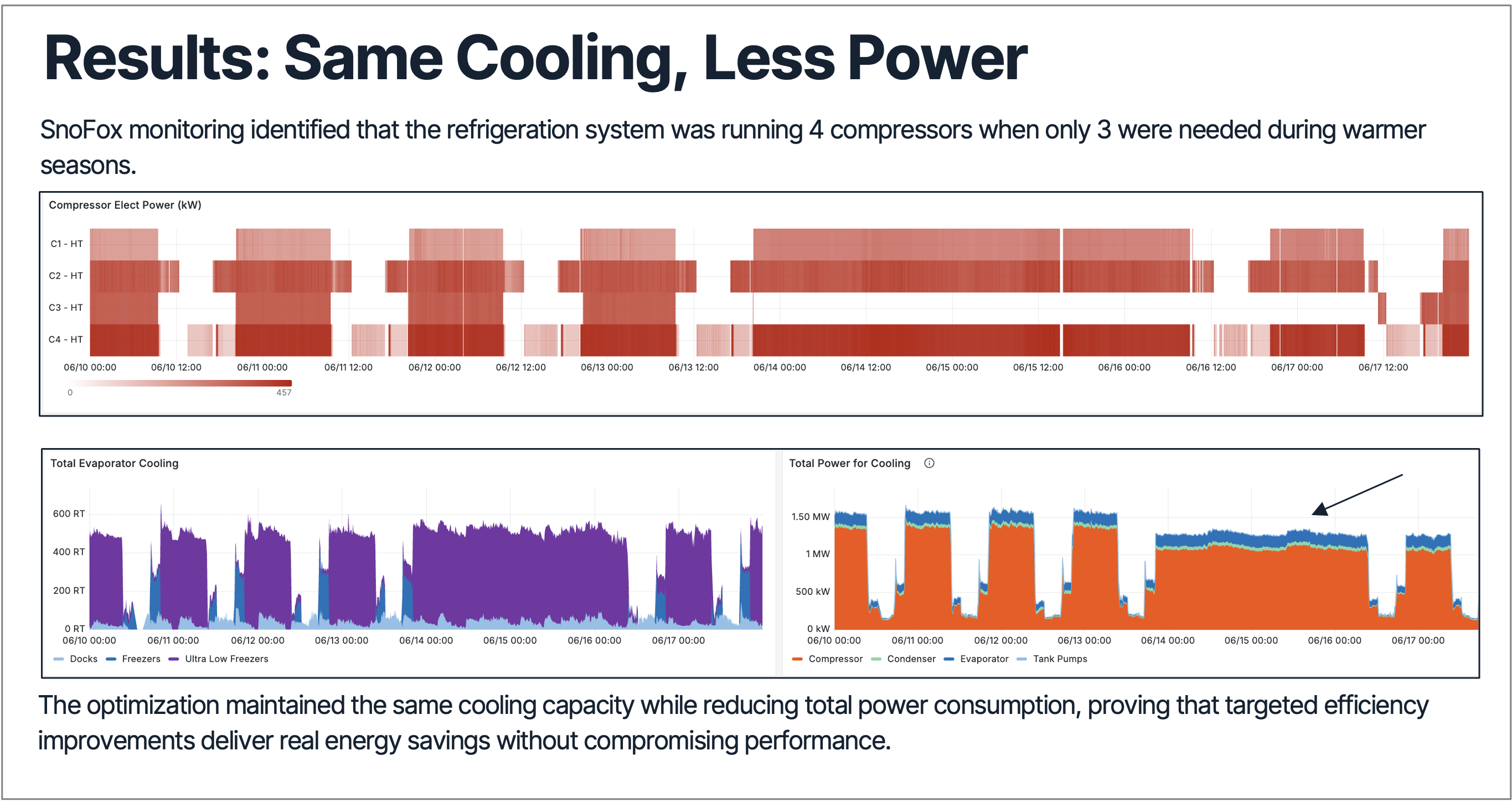

A real example: From Data to Impact

Effective sustainability management requires moving beyond assumptions to work with precise, actionable data. With SnoFox's component-level monitoring, it can reveal exactly where improvements can be made.

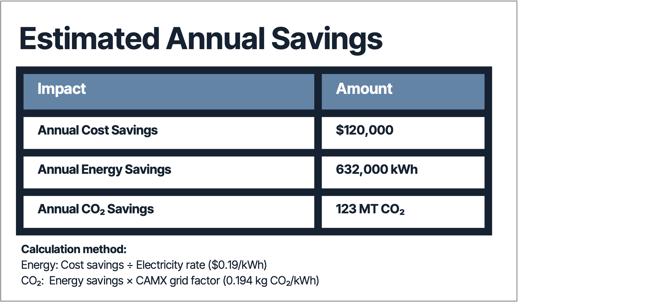

In one recent case, SnoFox's monitoring revealed high compressor usage in a facility's refrigeration system. Upon investigating, the SnoFox platform identified that the system was running 4 compressors during warmer seasons when only 3 were needed.

This finding revealed that this operational adjustment could save $120,000 annually in energy costs. Converting this to environmental impact calculates to a reduction of 123 metric tons of CO2 annually.

Ready to Unlock Your Facility's Potential?

Ready to enhance your sustainability program with precision data? SnoFox provides the component-level monitoring and analysis that goes beyond facility-wide energy data. With detailed visibility, efficiency optimization tools, and quantified reduction opportunities, you'll have the foundation for delivering measurable environmental impact.

Interested in seeing what energy reduction opportunities exist in your facility? Book a demo to learn how SnoFox can support your carbon reduction initiatives with actionable data and measurable results.